Popsicle Stick Bridges are surprisingly lightweight and strong. They're aesthetically interesting, elegant, economical, primitive, and sophisticated. A group of teenagers can build a city's worth of them in a weekend.

This is CNC'd "Kit-of-Parts" for a bed frame. It clicks together like Lego, or like Ikea.

This is the "Rigamajig Toy" designed by Cas Holman. It's a Kit-of-Parts that's Modular, Extensible, Scalable, and Reconfigurable. MESR summarizes the principles of the KOP approach. I want to design a system that makes complex and sophisticated projects feel like free and effortless play.

Cas Holman says "Good Toys make Good People." . I want to make plywood kits that click and bolt together into life-size popsicle stick bridges. This would be Popsicle Stick Factory, one of many business designed to run on The Good Kits Platform.

This is a CNC Router inside of a 20 foot shipping container. The image comes from Facit Homes, a British company that has applied digital fabrication techniques to homebuilding. This CNC-machine-in-a-container is what I would like to invest in. It is the core functional module in the Good Kits model. I have the money to buy the machine and associated equiptment; I'm looking for a place to put it, people to work with, and projects to work on. These machines are incredibly flexible. They can produce components for toy-scale projects, furniture-scale projects, or house-scale projects, and switch back and forth seamlessly.

I want work to feel like play.

This is Anji Play, the coolest thing ever. I would love to offer Anji Kits, at-cost or for free to schools.

Good Kids build Good Kits and Good Kits build Good Kids.

This is Street Lab, an organization in New York City that hosts pop up street events. Many of their street furniture systems are CNC'd plywood. I would love to work with them and develop more and different pop up structures, like, for example, life size popsicle stick bridges.

A functional shop setup could look like this: 2 20 foot containers with a roof structure between them. This setup be transported as one flat-bed truck load, and delivered anywhere in the country. This would give me 720 sq feet of work space, which is perfect to get started. The CNC machining center and associated equiptment gets installed in the containers. The containers are for storing raw material and finished parts. The central open space is a workspace/playspace. It could be a playstructure one day, and a boat building shop the next.

This is a CNC microhousing project called Shelter 2.0. Shelter 2.0 is open source, and would be available as a module in the Good Kits Ecosystem. I want to build one for myself, put it on the roof of my shop, design add-on modules like a kitchen and a shower, and offer it for sale as a kit. I am interested in selling kits for profit, selling them at-cost, or giving them a way for free, depending on the context. I want to keep my expenses low, develop some revenue streams, and then re-invest and re-direct those revenue streams in ways that are creative, equitable, generous, and socially responsible.

This is my first attempt at a kit-of-parts microhouse.

It is a lightweight system of bolt-together panels. I designed a rope hoist system for pulling the whole structure up and down from a rooftop in Brooklyn.

The panels are glued up from these plywood puzzle pieces, which are compact for transport, but assemble into a large, lightweight, impressive sculptural structure.

My dayjob is building things like this pop-up retail display for the luxury handbag company Burberry. Currently, I design and build structures that uphold and reenforce our current wasteful, unequal, and anti-ecological economic paradigm. I want to transition towards building resilient, scalable, rapidly-deployable alternatives.

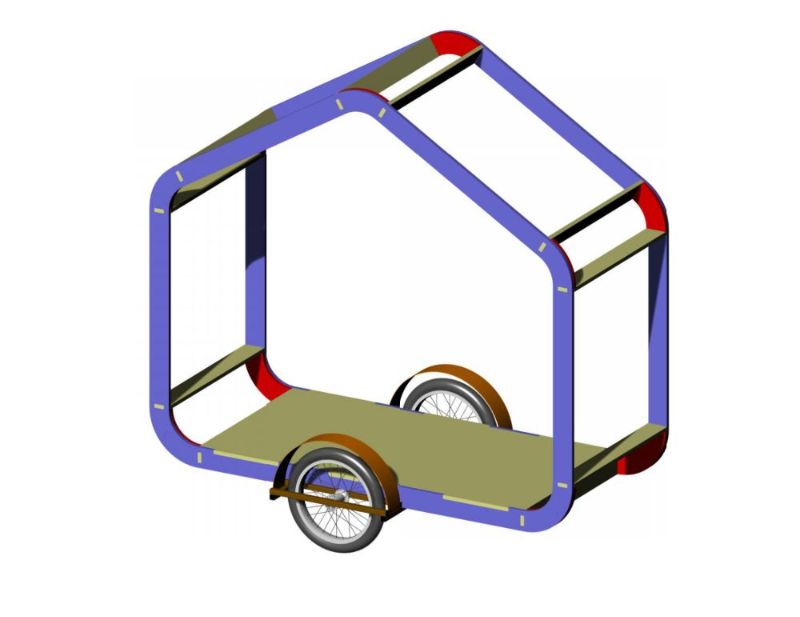

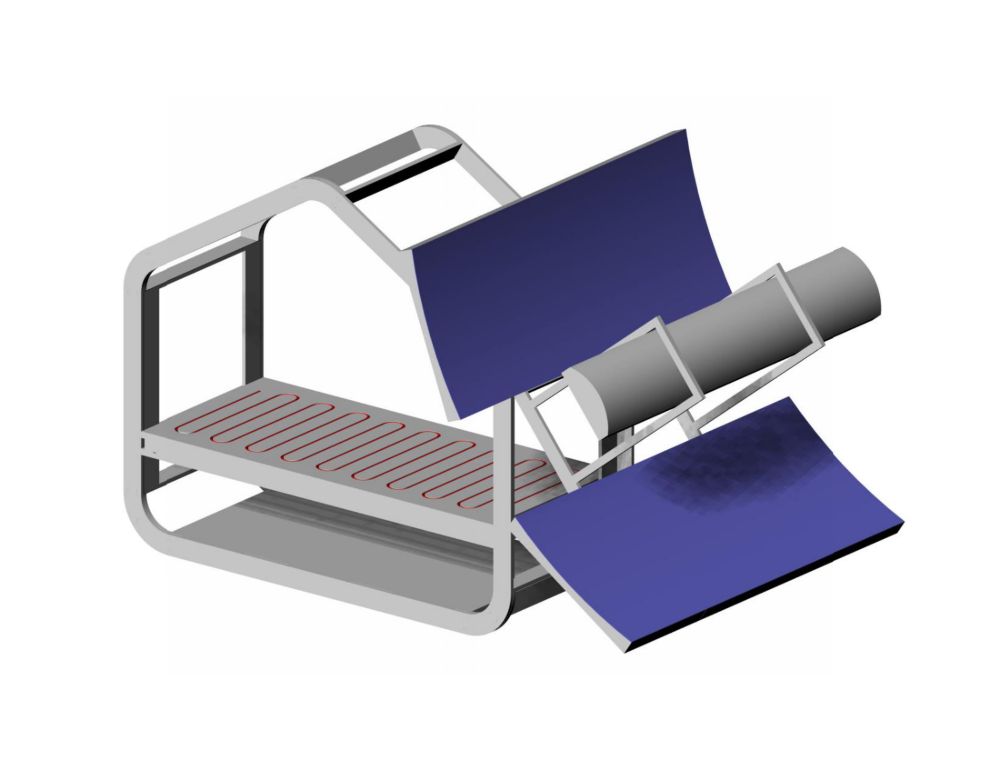

I designed this bicycle trailer as an open framework that can be configured for a wide range of applications.

You could add a solar heating module to make a structure for sitting of sleeping. You could make a mobile shower or kitchen, or a retail display booth, or even a miniature exhibition or museum space. It would be the perfect scale for a Museum of Popsicle Stick Structures.

This is my current bicycle trailer setup with a mobile espresso cart.

With this cart, I have earned as much as $75/hr. I want to design a micro deployable soup kitchen that is similar, but lighter, and more elegant. On the CNC, I could cut an Espresso Cafe / Soup Kitchen Combo Cart in 15 minutes. I could sell kits, give them out in exchange for equity, rent them out, lease them out, give them as gifts, etc. I'm interested in Financial Architectures, and I would like to experiment with all of the above arrangements.

This is the Wikkelhouse, a wrapped cardboard house system built on a CNC'd plywood skeleton. We could make something like that.

This is the Chesapeake Light Craft camper. The camper and the boat on top are built from CNC'd kits. CLC uses their CNC kits as the basis for classes and workshops. Boat Kits could be a part of the Good Kits Ecosystem.

This is a rolling electronics laboratory and radio communications platform, made out of cardboard, epoxy, and fiberglass. When I say you can build amazing things with Popsicle Sticks and Cardboard, this is the kind of thing I'm talking about.

I want to build a liveable future. That's going to require contributions from a lot of different directions. This proposed project is just my angle on that much larger endeavor. I think this could be a good angle. I think these are good, resilient, powerful, efficient ideas. They make sense from an engineering perspective, and I think that kids would like them. If you would like to help me work on this, send a message to

eamon dot email at gmail dot com